Taper Bushes

Taper bushes offer an economical and efficient way of fixing components to shafts

- Overview

- Dimensions

- Technical

- Downloads

The most cost effective and efficient way of fitting components such as chain sprockets, V-belt pulleys, timing belt pulleys, flexible and HRC couplings to shafts...

- Stocked in a wide range of metric and imperial bore sizes, all with integral keyway to DIN 6885 or BS 46 Part 1:1958

- Manufactured in cast iron

- Excellent concentricity with a clean, flush appearance

- Longitudinal split ensure a vice-like grip on the shaft

- No re-boring or keyways required

- Easy to fit and remove. No skilled labour or special tools required

- Interchangeable and re-useable

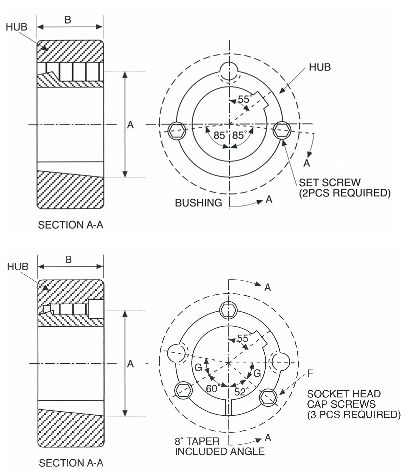

Dimensions for taper bushes 1008 to 3030

| Bush # | A | B | Screw | Bore range | Bore range | |

| mm | mm | qty | Size | Metric | Imperial | |

| 1008 | 35.00 | 22.30 | 2 | 1/4" x 1/2" | 9 - 25 mm | 3/18" - 1" |

| 1108 | 38.00 | 22.30 | 2 | 1/4" x 1/2" | 9 - 28 mm | 3/8" - 1.1/8" |

| 1210 | 47.50 | 25.40 | 2 | 3/8" x 5/8" | 11 - 32 mm | 1/2" - 1.1/4" |

| 1215 | 47.50 | 38.10 | 2 | 3/8" x 5/8" | 14 - 28 mm | 1/2" - 1.1/4" |

| 1610 | 57.00 | 25.40 | 2 | 3/8" x 5/8" | 14 - 42 mm | 1/2" - 1.5/8" |

| 1615 | 57.00 | 38.10 | 2 | 3/8" x 5/8" | 14 - 42 mm | 1/2" - 1.5/8" |

| 2012 | 70.00 | 31.80 | 2 | 7/16" x 7/8" | 14 - 50 mm | 3/4" - 2" |

| 2517 | 85.50 | 44.50 | 2 | 1/2" x 1" | 16 - 65 mm | 3/4" - 2.1/2" |

| 3020 | 108.00 | 50.80 | 2 | 5/8" x 1.1/4" | 25 - 75 mm | 1.1/4" - 3" |

| 3030 | 108.00 | 76.20 | 2 | 5/8" x 1.1/4" | 35 - 75 mm | 1.1/4" - 3" |

Dimensions for taper bushes 3525 to 5050

| Bush # | A | B | Screw | Bore range | Bore range | |

| mm | mm | qty | Size | Metric | Imperial | |

| 3525 | 127.00 | 64.90 | 3 | 1/2" x 1.1/2" | 35 - 100 mm | 1.1/2" - 4" |

| 3535 | 127.00 | 88.90 | 3 | 1/2" x 1.1/2" | 35 - 90 mm | 1.1/2" - 3.1/2" |

| 4030 | 146.00 | 76.20 | 3 | 5/8" x 1.1/4" | 40 - 100 mm | 1.3/4" - 4" |

| 4040 | 146.00 | 101.60 | 3 | 5/8" x 3.1/4" | 40 - 100 mm | 1.3/4" - 4" |

| 4535 | 162.00 | 88.90 | 3 | 55 - 110 mm | 2.1/4" - 4.1/2" | |

| 4545 | 162.00 | 115.00 | 3 | 3/4" x 2" | 55 - 110 mm | 2.1/4" - 4.1/2" |

| 5040 | 177.60 | 101.60 | 3 | 7/8" x2.1/4" | 70 - 125 mm | 2.3/4" - 5" |

| 5050 | 177.60 | 127.00 | 3 | 7/8" x 2.1/4" | 60 - 125 mm | 2.3/4" - 5" |

The installation of taper lock bushings is fundamental to the correct installation of couplings, weld on and bolt on hubs and universal joints. The procedure is quite simple.

To install

- Check the bushing and shaft sizes are correct!

- Ensure the whole bushing, shaft and the hub to be fitted is clean of oil, dirt or lacquer.

- Install the bushing in the hub, matching the ½holes in the hub with the ½ holes in the bushing. (Note – each hole will be threaded on the hub side only).

- Oil the threads on the set screws or cap screws provided and fit loosely into the assembly.

- Slide the hub and bush assembly onto the shaft and locate in the desired position.

- Tighten the screws evenly and alternately until tight (see recommended torque figures below). Note that the bush will tighten onto the shaft first, then draw the hub slightly up the taper. This may affect the final axial position of the hub on the shaft. You may have to make an adjustment to the starting position to accommodate this.

- Using a soft hammer or hammer and soft wooden block, tap the taper bush at the larger end. Retighten the screws to the recommended torque figures. Repeat if required.

- Fill remaining holes with grease to prevent a build op of dirt in service.

- Shafts should be aligned using simple laser alignment tools to maximise coupling life.

- After the system has been run under load for a short time, the screws should be checked for tightness.

| Bush size | 1008 | 1108 | 1210 | 1610 | 1615 | 2012 | 2517 | 3020 | 3030 | 3525 | 3535 | 4030 | 4040 | 4535 | 4545 | 5040 | 5050 |

| Screw torque (Nm) | 5.6 | 5.6 | 20 | 20 | 20 | 30 | 50 | 90 | 90 | 115 | 115 | 170 | 170 | 190 | 190 | 270 | 270 |

| Screw size | 1/4" | 3/8" | 7/16" | 1/2" | 5/8" | 1/2" | 5/8" | 3/4" | 7/8" | ||||||||

To remove

- Remove all screws. Oil the threads and insert into the holes that are threaded on the bush side. Note – you will not need all the screws to remove the bush.

- Tighten the screws alternately until the bushing is loosened.

- A gentle tap with a hammer may be required to loosen the parts.